Much of the oil produced worldwide is accompanied by water

in an emulsion that requires treating. Even in those fields where there is

essentially no initial water production. Technical Data used in the field

explained in petroleum courses in Islamabad.

water cuts may increase in time to the point where it is necessary to treat the

emulsion. Water content of the untreated oil may vary from a fraction of I % to

over 90%. To prevent increased transportation costs, water treatment and

disposal costs, and deterioration of equipment, purchasers of crude oil limit

the basic sediment and water (BSSCW) content of the oil they purchase. Limits

vary depending on local conditions, practices. and contractual agreements and

typically range from 0.2 to 3.0%. BY&W is usually predominantly water but

may contain solids.

The solids contained in the BS&W come from the producing

formation and consist of sand. silt, mud, scale. And precipitates of dissolved

solids. These troublesome solids vary widely from producing field to field.

zone to zone, and well to well.

Purchasers may also limit the salt content of the oil. Removing

water from the stream decreases the salt content. Salt content along with

BS&W are the two important crude purchasing requirements. Some more details

of petroleum courses in Islamabad are as under.

An emulsion is a heterogeneous liquid system consisting of

two immiscible liquids with one of the liquids intimately dispersed in the form

of droplets in the second liquid. An emulsion is distinguished from a simple

dispersion of one liquid in another by the fact that, in an emulsion, the

probability of coalescence of droplets on contact with one another is greatly

reduced because of the presence of an emulsifier, which inhibits coalescence.

Such inhibition is not present in a dispersion.

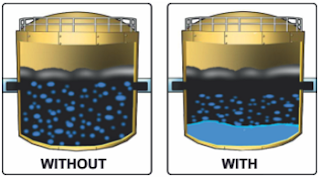

The stability of the emulsion is controlled by the type and

amount of surface-active agents and/or finely divided solids. which commonly

act as emulsifying agents or emulsifiers. As shown in Fig. 19.1, these

emulsifying agents form interfacial films around the droplets of the dispersed

phase and create a barrier that slows down or prevents coalescence of the

droplets.

The matrix of an emulsion is called the external or

continuous phase. The portion of the emulsion that is in the form of small

droplets is called the internal, dispersed, or discontinuous phase. The

emulsions considered in this chapter consist of crude oil and water or brine

produced with it. TSK Training for Skills and Knowledge is the best institute

in Rawalpindi Islamabad for Pakistani Students who wants to join petroleum courses in Rawalpindi.

No comments:

Post a Comment